L. A. King helped an OEM customer by providing a cost-effective design solution that saved the end-user money and allowed our customer to enjoy a higher profit margin.

Cost-Effective Design for Diverter Gate Pillows

Power Division Customer

Customer Intro

An original equipment manufacturer (OEM) that provides new, upgraded, and replacement equipment and parts for gas-burning power plants worldwide.

The Problem

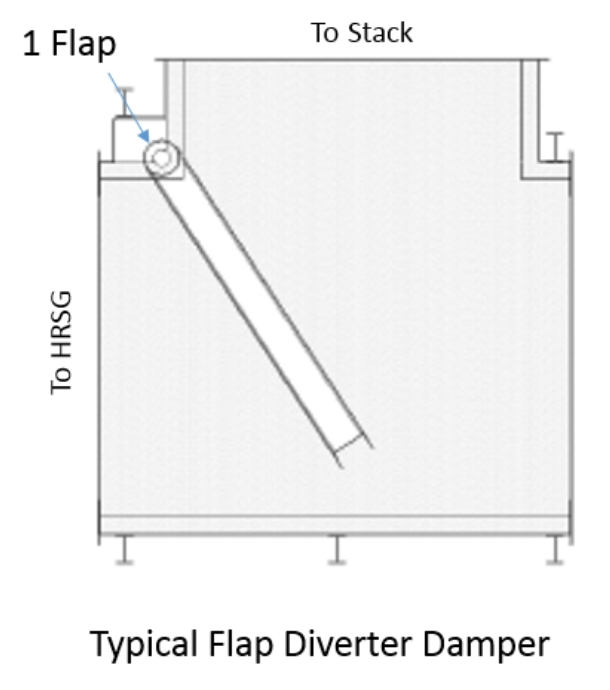

The OEM customer approached us with drawings for a “diverter gate pillow.” The pillows are used to prevent hot gas leaks in a gas turbine system by providing insulation around the diverter gate. The customer’s design called for a stainless steel frame and non-standard hardware, which would be expensive to fabricate.

The Solution

We reviewed the customer’s drawings and proposed a design that maintained the original form, fit, and function of the pillows. Our design was far less expensive to fabricate and used standard attachment hardware, saving the end-user money.

The Results

Our customer’s customer approved our modifications, and we successfully made the parts they needed. Our cost-effective design not only saved the end-user money but also helped our customers enjoy a little higher profit margin.

Conclusion

Our ability to find a cost-effective solution while maintaining the original design specifications demonstrates our commitment to providing high-quality products that meet our customers’ needs while maximizing their ROI.

Back to Case StudiesRelated Case Studies

Closing a Metal Building Roof with Laminated Insulation

See how we helped a metal building insulation customer with a last-minute request as they had a building with an open roof that needed to be closed before storms arrived.

Read MoreWorking Through Supply Chain Challenges in HVAC Industry

See how we worked through supply chain issues and helped one of our sheet metal fabricator customers stay in business.

Read MoreCost-Effective Design for Diverter Gate Pillows

See how we provided an OEM customer with a solution for diverter gate pillows. Our cost-effective design helped them a enjoy a higher profit margin.

Read More